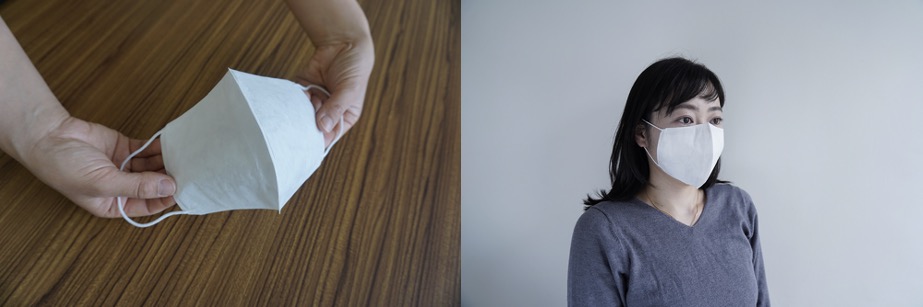

Seiko Epson Corporation (TSE: 6724, “Epson”) will apply its original Dry Fiber technology to manufacture face masks for its employees in Japan. Dry Fiber technology, which is also used in Epson’s PaperLab A-8000 in-office dry paper making system, is a dry process that has until now been used to turn used paper into new paper inside the office. The masks will be made not from used paper, but from functional fibers and will be manufactured at the company’s Kanbayashi and Suwa Minami Plants in Nagano, Japan, where the majority of its domestic employees are located. Epson expects to begin manufacturing the masks from the end of May. The company does not currently plan to manufacture the masks for sale.

These masks respond to growing demand for face masks for protection against the novel coronavirus (COVID-19). Manufacturing the masks in-house will allow Epson to donate 100,000 surgical masks it had purchased as part of its business continuity plan (BCP) to local authorities and medical institutions in Nagano, where needs for personal protective equipment (PPE) have been expanding rapidly.

The company will also donate 5,600 face shields to the same organizations.

See here for more information on PaperLab and Dry Fiber technology.